01

Inspection of painting of houses and buildings

An independent advice

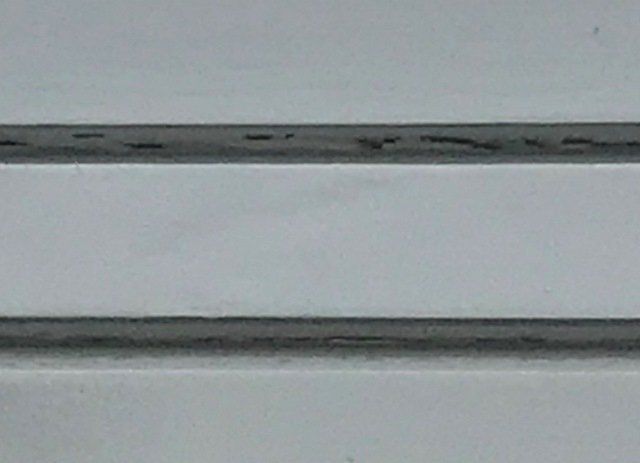

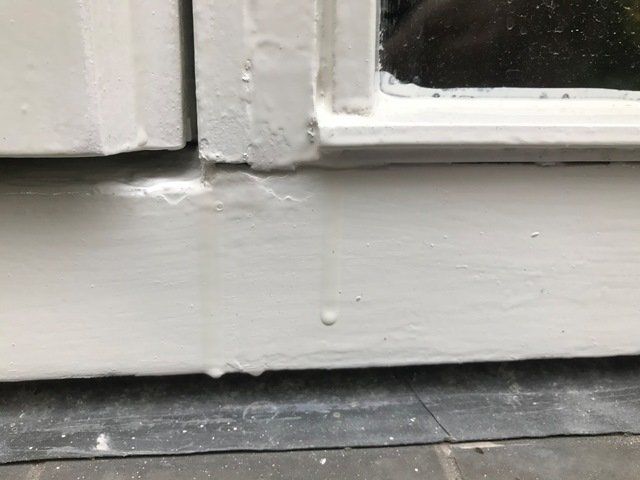

Did your home just have a paint job and do you need an independent final inspection? Or would you like an independent quality control during the execution of the painting work on your home? Then you've come to the right place! I check the quotation for you, I supervise the painting work and I carry out a final inspection of your painting. After carrying out (outdoor) painting on your home, it is advisable to have an independent final inspection carried out. On the basis of an inspection list, the painting is then checked, various measurements and visual inspections are carried out and the quality of the painting is visualized for you. You will receive an inspection report which lists any shortcomings in relation to the quotation that the painter will then arrange for you. In this way you will not have to worry about your painting in the coming years. An inspection during pre-treatment and / or during painting is also recommended because there is the possibility to adjust in time. Proper pre-treatment (degreasing, de-rusting, sanding, filling) is, for example, essential for the life of your painting. I have extensive experience with the inspection of industrial paint systems, for example applied to steel constructions, pressure vessels, gas compressors and piping, but also to cargo ships and super yachts. I am in possession of various paint inspection certificates (NACE CIP level 2, FROSIO level 3) and I own VCA VOL. I have also regularly done exterior painting on homes.

Book now

02

Coating advice and coating inspections

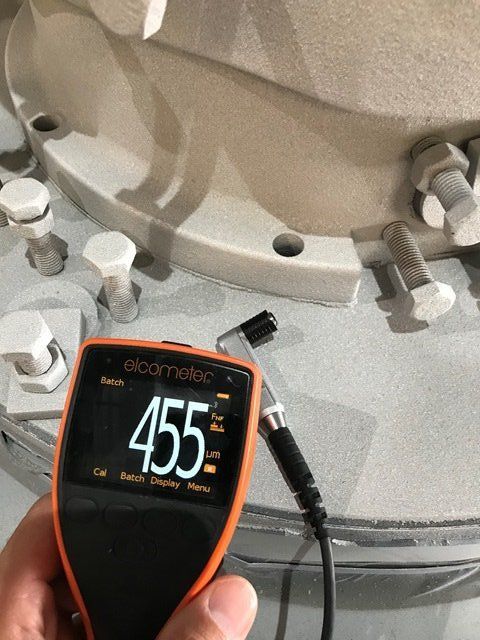

FROSIO 3 and NACE CIP 2 certified

I carry out coating inspections according to the ISO, NACE and NORSOK requirements and take care of the assessment of coating procedures, the determination of the test and inspection plan and the acceptance criteria. I have extensive experience with the inspection of industrial paint systems, for example applied to steel constructions, pressure vessels, gas compressors and piping, but also to cargo ships and super yachts. I am in possession of various paint inspection certificates (NACE CIP level 2, FROSIO level 3) and I own VCA VOL. I have experience in qualifying personnel and qualifying the coating procedure (CPT) according to the requirements of the NORSOK M-501. Corrosion mechanisms During my career I have specialized in recognizing degradation and corrosion mechanisms and preventing corrosion by means of the right choice of materials and the correct design of the installation and protection against corrosion by applying protective coatings. It is important that during design, the weldability of, for example, a steel construction (it is possible to lay a smooth weld without welding spatter) and the accessibility for cleaning, blasting and spraying. During the operation of, for example, a gas compressor, the following corrosion mechanisms may occur: general corrosion, galvanic corrosion, crevice corrosion, intercrystalline corrosion, pitting corrosion, crack-forming stress corrosion cracking (Corrosion Cracking) and corrosion under insulation.

Book now03

Quality assurance and quality controls

During the new construction of pressure equipment, industrial installations and gas compressor skids